How does the size of the screw affect the speed of the boat. Overview of the screw on the boat motor Yamaha.

Page 1 of 2

Before buying a screw for a boat or a boat, you need to decide on the goal - whether you need to achieve the highest possible speed or maximum load capacity. With one screw it is impossible to solve these problems, but you can choose a compromise - a screw for the most used modes.

It would be more correct to have two screws on board and use them depending on the load. Especially the second screw - spare.

Boat screws vary in diameter, pitch, number of blades and the material from which the screw is made. The diameter and pitch are usually stamped or cast on the side or on the hub of the propeller.

Interpretation of propeller marking:

(1) Diameter of the propeller (in inches)

(2) Propeller pitch (in inches)

(3) Type of propeller (brand)

With the same screw can you achieve maximum speed and maximum payload?

Not. To achieve high speed, pitch or diameter is used, unsuitable for carrying capacity - where completely different working conditions are used. If you want to do with one screw, then decide what is most important, based on this, and choose a screw.

Which screw is better - 3 or 4 blades?

For most boats, 3-blade propellers are recommended. These screws provide good acceleration and performance at base speed.

A three-bladed screw has less resistance and allows (theoretically) to develop greater speed. Four-bladed has a greater emphasis, the speed with this screw on modes from slow to 2/3, should be higher.

Screws with 4 blades have a greater disk ratio, such screws are recommended for heavier boats and boats with high performance hulls equipped with more powerful engines.

Compared to the 3 blades, they “work” better when accelerating, are most effective when towing water skiers and parachutists, and have less vibrations at high speeds.

For my boat there is a screw of 13 "and 14" diameter. A smaller diameter with a large pitch is the same thing?

a - diameter of the screw; b - screw pitch.

Step can not replace the diameter. The diameter is directly related to the engine power, the number of revolutions per minute and the speed your requirements indicate.

If the operating conditions assume a 13 "diameter, then with a 12" installation, its efficiency will be reduced.

Is it necessary to use high temperature to install or remove the screw?

Heat should never be used when installing a screw, and therefore is rarely required to remove it.

If it is not possible to remove the screw using a soft hammer, a light, gentle heating with a blowtorch can help. Do not use a welding torch, as a quick, harsh heat will change the structure of the bronze, creating internal stresses that can split the hub.

What is the advantage of using the second screw - left rotation?

Two screws working in the same direction on the boats (ships) create a reactive moment. In other words, the two right screws will tilt to the left.

Two screws of opposite rotation on identical engines will eliminate this reactive moment, because the left screw will balance the right screw. This will lead to better linear motion and control at high speed.

Therefore, 2 motors with screws of different rotation are often installed.

The three most common screw materials are composite plastic, aluminum, and stainless steel.

Each has differences in price and operation. (Bronze - usually used on slower boats and yachts.) The material of the screw determines its use on engines of various capacities.

Plastic boat screws - used on engines less than 50hp (preferably less than 20hp). Many water motorists use a plastic screw as a spare, and not as a regular one. Although they are cheaper, their effectiveness is limited by blades sagging under load, unable to maintain their shape, due to the relative weakness of thin plastic blades.

Most plastic screws cannot be repaired, although some blades can be bought individually for replacement. So far, no screws have better properties than screws made of metals - a good screw should have a long service life and be repairable. While the available plastics lose in all these parameters.

Aluminum screws - Most boats are equipped with aluminum screws. Aluminum screws are relatively inexpensive, easy to repair, and under normal conditions can last for many years. Aluminum screws are used on engines up to 150hp.

Aluminum screws are a bit more expensive than plastic, but they work more efficiently due to the reduced thickness of the blade, they bend less under the load, they keep the shape of the blade better. Aluminum blades with a small damage are sufficiently maintainable.

Stainless steel - more expensive, but much more durable and durable than aluminum. Stainless steel is expensive, but it justifies the price, because it transmits power with the least loss. The most versatile and expensive screws are stainless steel. Steel is extremely durable, allowing the blades to be as thin as possible, reducing the resistance in the water, and due to its strength - the deflection is eliminated. Despite the fact that the blade has a small thickness, it is quite strong.

Steel is maintainable after strikes on a flooded obstacle, but there is another side to all the advantages - more likely to bend the shaft.

Steel propeller or aluminum propeller

A popular topic in the powerboat forums: some attribute the miraculous properties to steel screws, while others prove that this is nothing more than a brilliant bluff, which over time destroys the outboard motor.

Initially, the outboard motor can be sold without a screw at all - as a rule, these are models of medium and high power. In this case, the owner selects the propeller based on the available boat and its needs.

As a rule, the steel screw is purchased to the already existing aluminum one, which passes into the discharge of a spare engine on the boat. Getting the steel screw the vodkotornik compares such main indicators:

Price - The steel screw is several times more expensive than aluminum.

Weight - The steel screw is several times heavier. This does not affect the acceleration dynamics at all, although such arguments are often put forward by "experts."

Fact: riders who fight in fractions of seconds of acceleration speed use only steel screws.

The emphasis created by the propeller when driving vodkomotki, tens, and hundreds of pounds - against this background, the weight of the screw itself is almost imperceptible.

The cause of the wear of the propeller shaft bearings may be an imbalance of the blades, which causes vibration when the propeller rotates.

outboard motor has no clutch or friction synchronizers - the gears of the forward and reverse gear are engaged rigidly, through the cam clutch - “ratchet”. Softens the "blow" when you turn on only the rubber shock absorber, pressed into the screw hub.

Out of position one - idle speed should be adjusted and be normal (usually 650–850 rpm).

Design - the blade section (thickness) of the steel screw is twice as thin as aluminum. This allows you to get higher efficiency at high speeds.

Aluminum screws are made by a simple chill casting method, which imposes certain restrictions on the configuration and does not differ in precision accuracy.

Steel screws are cast in special shapes, which provides higher accuracy and allows you to create almost any shape. Virtually every steel screw is brought by hand. From here the high cost price and the price of steel screws.

Propellers for outboard motors and ways to increase speed.

What is useful to know from theory.

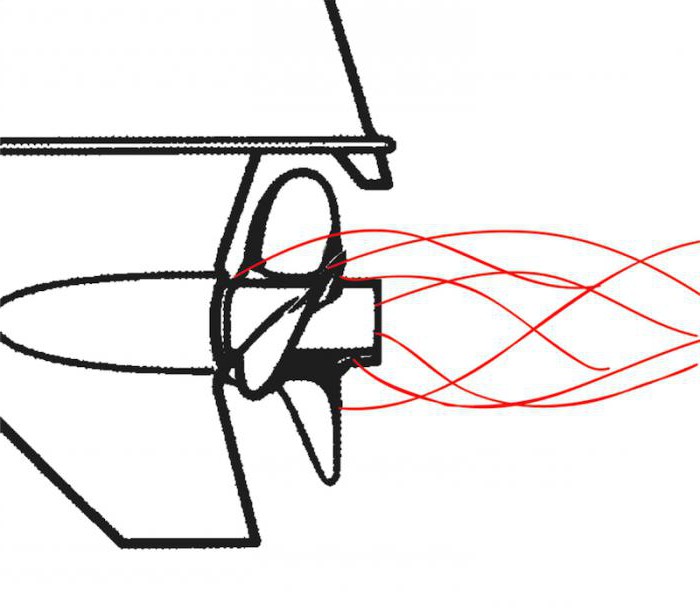

How the propeller works (fig. 211). Propeller converts the rotation of the engine shaft to the stop - the force pushing the vessel forward.

When the screw rotates on the surfaces of its blades, facing forward - in the direction of the vessel’s movement (sucking), a vacuum is created, and on the backward (pumping) engines - an increased water pressure. As a result of the pressure difference on the blades, a force arises.Y(it is called lifting). Decomposing the force into components - one directed in the direction of the vessel’s motion, and the second perpendicular to it, we obtain the forceP creating propeller stop and force T,forming torque, which is overcome by the engine.

The stop is largely dependent on the angle of attack of the blade’s profile (fig. 212). The optimal value of the angle of attack for high-speed cutter screws 4-8 °. If a is more than the optimum value, then the engine power is unproductively expended to overcome a large torque; if the angle of attack is small, the lift and, therefore, the emphasis Rwill be small, the engine power will be underutilized.

In the diagram illustrating the nature of the interaction between the blade and the water, the angle of attack a can be thought of as the angle between the direction of the velocity vector of the incident flow to the bladeW and injecting surface. Flow velocity vectorW formed by geometrical addition of translational velocity vectors V apropeller along with vessel and rotational speedv r i.e., the speed of movement of the blade in the plane perpendicular to the axis of the screw.

Screw surface of the blade. On rice 212 shows the forces and velocities acting in any one specific cross section of the blade located on a certain radiusr propeller screw. Rotational speedv rdepends on the radius at which the section is located (v r = 2π r n,where p- screw speed, rev / sec). The speed of the forward movement of the screwv a remains constant for any section of the blade.

So the morer i.e. the farther the considered section is located from the axis of the screw, the greater the circumferential speed v r, and therefore the total speedW.

Since the side V ain the triangle of considered velocities remains constant, then as the blade section is removed from the center, it is necessary to turn the blades at a large angle to the screw axis so that the angle of attack and maintains the optimum value, i.e., remains the same for all sections. Thus, a screw surface with a constant pitch is obtained. N.Recall that the pitch of the screw is the movement of any point of the blade along the axis for one full turn of the screw.

Since the side V ain the triangle of considered velocities remains constant, then as the blade section is removed from the center, it is necessary to turn the blades at a large angle to the screw axis so that the angle of attack and maintains the optimum value, i.e., remains the same for all sections. Thus, a screw surface with a constant pitch is obtained. N.Recall that the pitch of the screw is the movement of any point of the blade along the axis for one full turn of the screw.

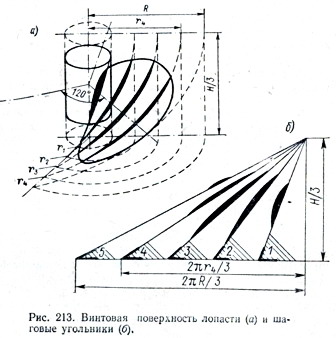

Introduce the complex helical surface of the blade helps rice 213. When the screw is working, the blade glides along guide rails that have different base lengths on each radius, but the same height is a step, and rises by one turn by the amount of 1 step N.The product of the same step by the number of revolutions (Hn ) is the theoretical speed of movement of the screw along the axis.

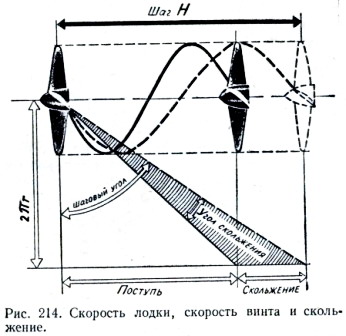

Boat speed, screw speed and glide.

When moving the hull of the vessel drags the water behind it, creating a fair flow, therefore the actual speed of the propeller meeting with waterV a always slightly less than the theoretical screw speed NpIn high-speed gliding motorboats, the difference is small — only 2–5%, since their hull slides through the water and hardly “pulls” it along. For boats with an average speed, this difference is 5-8%, and for low-speed displacement deep-set boats it reaches 15-20%.

Now compare the theoretical screw speed. Npwith the speed of its actual movement V a regarding water flow (fig. 214). Let it be "Kazanka", going under the motor "Whirlwind" at a speed of 42 km / h (11.7 m / s). The rate of flow of water on the screw will be 5% less: V a = (1-0.05) * 11.7 = 11.1 m / s.

Now compare the theoretical screw speed. Npwith the speed of its actual movement V a regarding water flow (fig. 214). Let it be "Kazanka", going under the motor "Whirlwind" at a speed of 42 km / h (11.7 m / s). The rate of flow of water on the screw will be 5% less: V a = (1-0.05) * 11.7 = 11.1 m / s.

Propeller on the "Whirlwind" has a pitch H =0.3 m and speed n =2800: 60 = 46.7 p / s. Theoretical screw speed.

Np = 0.3 * 46.7 = 14 m / s.

So we get the difference NP - V a =14 - 11.1 = 2.9 m / s.

This quantity, called slip, causes the propeller blade to operate at an angle of attack a to the flow of waterW . The ratio of slip to the theoretical screw speed in percent is called relative slip. In our example, it is

S = ( HH- V a) \\ H n = 2.9 \\ 14 = 0.207 = 20.7%

The maximum value (100%) of the glide is achieved when the propeller is operated on a ship moored to the shore. The smallest slip (8-15%) have the screws of light racing motorboats at full speed; for propellers of planing pleasure boats, the slip is 15–25%, for heavy displacement boats 20–40%, and for sailing yachts having an auxiliary engine, 50–70%.

Light or heavy propeller.

The diameter and pitch of the propeller are the most important parameters, which determine the degree of use of engine power, and hence the possibility of achieving the highest speed of the vessel.

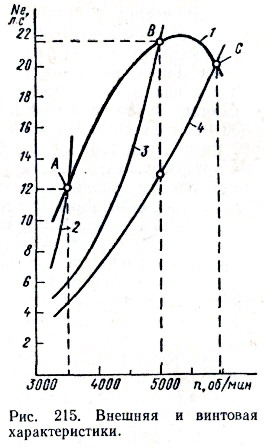

Each engine has its own so-called external characteristic - the dependence of the power removed from the shaft on the number of revolutions of the crankshaft with the carburetor throttle fully open. Such a characteristic for the Whirlwind outboard motor, for example, is shown in rice 215 (curve 1). Maximum capacity of 22 liters. with. engine develops at 5000 rpm.

The power that is absorbed in this boat by the propeller depending on the engine speed is shown in the same figure not by one, but by three curves - by screw characteristics. 2, 3 and 4,each of which corresponds to a specific propeller, i.e. a screw of a certain pitch and diameter.

Both with increasing pitch and with increasing screw diameter above optimal values, the blades capture and throw back too much water; the emphasis increases, but at the same time the required torque on the propeller shaft also increases. Screw characteristic 2 such a screw intersects with the external characteristic of engine 1 at point A; This means that the engine has already reached the maximum-maximum torque value and is unable to turn the shaft with a large number of revolutions, that is, it cannot develop the rated speed and the corresponding rated power. In this case, the position of the point BUT shows that the engine gives only 12 liters. with. power instead of 22 liters. with. Such a propeller is called hydrodynamically heavy.

On the contrary, if the pitch or diameter of the screw is small (curve 4), the stop and the required torque will be less, so the engine will not only easily develop, but will also exceed the rated speed. Its mode of operation will be characterized by point C. As we can see, even in this case the engine power is not fully used, and work at too high revolutions is associated with dangerously large wear of parts. It should be emphasized that since the stop of the propeller is small, the vessel will not reach the maximum possible speed. Such a screw is called a hydrodynamically light.

For each particular combination of vessel and engine, there is an optimal propeller. For the example in question, this optimal screw has a characteristic 3, which intersects with the external characteristic of the engine at point AT,corresponding to its maximum power.

This can be illustrated by such an example. Dural "Kazanka" with a 20-horsepower "Whirlwind" motor, having a standard propeller with a diameter of 240 and a pitch of 300 mm, with two people on board, reaches a speed of 42 km / h. If the same motor with the same screw is put on another boat - “Neptune”, heavier and having other lines, its speed with the same load will be 36 km / h, and with four passengers it will decrease to 14 km / h. Rowing propeller, which is close to optimal for Kazanka, becomes heavy on Neptune. Replace it with another screw having the same diameter, but the pitch is reduced to 240 mm. The speed of the Neptune (at the same power) increases to 41 and 36 km / h, respectively, only due to the fact that the propeller has become close to the optimum for this boat under this load.

When calculating the screw, its pitch and diameter are calculated taking into account the water resistance to the movement of the vessel at a certain draft (load) and at a given speed of the vessel, having in mind a certain number of revolutions and the power of the installed engine.

The general rule is this: for lightweight, fast boats, screws with a large pitch or step ratio are required. N \\ D,for heavy and slow - with less.

With commonly used engines with a speed of 1500-5000 rpm, the optimal step ratio N / D is: for racing motorboats and speedboats 0.9-1.4; lightweight pleasure boats 0.8-1.2; displacement boats 0.6-1.0 and very heavy low-speed boats 0.55-0.80. It should be borne in mind that these values are valid if the propeller shaft makes about 1000 rpm for every 15 km / h speed of the boat; with a different number of revolutions of the shaft rotation it is necessary to use a gearbox.

The diameter of the screw significantly affects the engine load. For example, when increasing D only 5% has to increase engine power by almost 30% to get the same number of revolutions of the screw. This should be taken into account if it is necessary to “lighten” a heavy screw: sometimes it is enough just to trim the ends of its blades a little.

Using the standard propeller for the outboard motor, the owner of the craft over time begins to think about the possibilities of improving the speed of the vessel. There are several key points that determine here: the weight of the boat, the power of the engine and, in fact, the efficiency of the propeller. And if to deal with the first two qualities is not difficult, then increase the speed of movement, without resorting to buying a new motor, allows only competent selection of a new screw.

How important is it to choose the right propeller for the outboard motor?

Outboard outboard motor due to the characteristics of the structure of the gearbox does not allow to switch gears. Accordingly, the gear ratio here remains constant. Therefore, to squeeze the maximum power out of the existing engine allows only a correctly selected propeller for the outboard motor.

Choosing a good screw allows you to improve the gliding output, increase the maximum carrying capacity of the craft or its speed, accelerate the motor. Among other things, a competent choice contributes to saving fuel burned, reducing noise while moving.

Propellers for outboard motors: variations

A variety of individual brands of outboard engines promotes the use of a wide range of propellers. Propellers for outboard engines differ according to the following parameters:

- The pitch of the screw is the distance that the swimmer passes in the course of making one complete rotation of the product, not taking into account the slip.

- Diameter - a circle that describes the most remote from the center point of the blades.

- The number of blades - often set screws with 3 blades, less often - with 2 or 4.

- Production materials - stainless and carbon steel, plastic, aluminum.

Diameter

The defining characteristic when choosing the considered part is its diameter. As a rule, when selecting a propeller for a boat's boat motor, preference is given to products with the largest external diameter. For boats, where the main focus is on the speed of movement, screws are selected, the blades of which describe a circle of smaller diameter.

Screw pitch

It is one of the most important qualities that should be given special attention when choosing a boat screw. As mentioned earlier, the step is the distance traveled by one complete revolution of this part. For example, a product with a diameter of 13 inches (35 cm) has a step of no more than 50 cm. You can deal with the selection of the required parameter by directly choosing the propeller for the Suzuki boat motor or another model of the engine already in place.

Removal of the blade

Another important characteristic is the angle between the perpendicular of the axis of the hub and the rear edge of the blades. Selecting propellers for boat engines "Yamaha" and other engines, attention should be paid to products with a large lead, which provides the best performance with significant resistance to the surface of the water.

An increase in the drift rate on fast and lightweight swimming vehicles helps to maintain a stable, optimal position of the boat and, as a result, to reduce the hydraulic resistance during movement.

Number of blades

Selecting a single propeller for the Suzuki outboard motor, as well as other popular engine models, should be done if significant vibration during movement is not a nuisance factor. If you want to achieve the best balance between vibration and efficiency, preference should be given to the two-bladed version.

The greater the number of blades have propellers for boat engines "Yamaha", the more smooth their work, but less efficiency. Perhaps for this reason, most models have three blades, which helps to achieve the perfect balance in terms of vibration, productivity, cost and size.

How to choose a suitable screw?

As already noted above, one propeller for the Tokhatsu outboard motor, as well as for other engine models, can give an advantage in one area, but noticeably lose in another. Therefore, the final decision should be made based on the characteristics that look the most significant in the current situation.

The key when choosing a screw for the outboard motor is the value of the number of revolutions of the engine. If the maximum is quickly achieved with full gas and a small loading of the craft, the screw is correctly selected. If, under these conditions, the motor does not give the highest revs, perhaps you should install a smaller screw.

When a large thrust is required to move a significant amount of cargo or, if necessary, tow other swimming facilities, take large diameter screws. If this requires high speed, it is better to give preference to options that are smaller in diameter, but with an increased pitch. This contributes to the creation of the required speed.

In general, indicators of the pitch and diameter of the screw for the outboard motor should be presented in the form of scales, which need to be balanced. If you need to achieve the highest possible revolutions of the boat engine, you can reduce the diameter by increasing the step, in a different situation - to do the opposite. Much here depends on the type, characteristics of the swimming facility, features of the engine and the method of its operation.

The choice of the propeller is a pressing issue for all people using motorized swimmers. Without it, the full and maximum realization of the engine's capabilities is impossible, since it does not have the ability to change gears on boats.

Using the right device allows you to get the following benefits:

- Reduced fuel consumption.

- Lower noise background.

- Improved engine performance.

- The possibility of achieving greater speed or increase in load capacity.

- Reduced water resistance while the boat is moving.

Varieties

To select and purchase the most suitable propeller, you should first understand the existing classifications. There are many different criteria for their division, the most significant of them are discussed below:

- Indicator of the distance that the screw is able to overcome when making one turn. This criterion is called the step, the slip is not taken into account.

- The diameter is the extreme points of the circle.that is created by rotating the blades.

- The ratio of the total area of all blades and the area of diameterThis criterion is commonly referred to as a disk relation.

- The number of blades that can be 2, 3, 4 or 5 pieces depending on the design features of the selected model. To date, the most common three-blade options.

- The material that was used for manufacturing. The most common models of various aluminum alloys, carbon steel, brass, stainless steel or plastic. Bronze devices are less popular because they are too costly in the absence of visible advantages over brass counterparts. Plastic models are made of modern and durable material, but the metal versions still remain more reliable and have a long operating life.

- Features of the hub designon which the exhaust method also depends.

Marking

Each propeller necessarily has a special marking that can be applied to its blades or directly on the hubs; All dimensions are in inches.

Marking devices today is carried out in different ways, the most common examples are listed below:

- 1¼х15 – G - in this example, there are two numerical values, they denote the indicators of the diameter of the blades and the pitch of the device.

- 3x10-3 / 8x11R - is a more detailed marking, which shows that the device is equipped with three blades and has a right-hand rotation.

- 3213-101-14 - is a catalog marking, the decoding of the articles should be present in the attached instructions or on the packaging.

Do the calculations

To date, there are a large number of different software that allows you to calculate the optimal parameters of the propeller, taking into account the specified parameters.

It is believed that the most accurate calculations are formed by programs that use the Pampel diagrams for these purposes. However, even in this case, errors are allowed, so the final selection of indicators is carried out only by test plants.

To obtain the most accurate calculations, the following significant factors should be considered:

- Dimensions and weight of swimming means.

- Features form the bottom of a motorboat.

- The volume of water that is displaced by the boat.

- The presence of longitudinal or transverse redans, reducing resistance.

- Engine performance.

- Reduction rates.

The main task is to obtain the skill to perform the most accurate calculations with the minimum amount of information. This will require the following information:

- Gear Ratiowhich can be viewed in the documentation attached to the engine.

- Turns of the maximum power of the motor. This information is applied directly to the engine or in the engine compartment, in the absence of this information, you can check this information with the manufacturer or look at its official website.

- Maximum speed to be achieved. It is necessary to present real indicators that can be obtained by comparing engine power and boat features.

The following formula is usually used to calculate the step:

(750x (desired maximum speed)) / number of revolutions of the shaft.

For the exact selection of the device, the resulting step indicator should be used as follows:

- The diameter of the device and its pitch are interrelated indicators, but even at a known pitch there will be about 2-3 models with different diameters. Here it is necessary to take into account the maximum allowed engine power: the higher it is, the larger must be the diameter of the screw.

- If possible, it is recommended to ask the seller to carry out test tests or take a screw with bail in increments that corresponds not only to the calculated indicator, but also to values close to it. This will allow in practice to verify the correctness of calculations by measuring the speed and choose the most suitable option.

Selection rules

Criterias of choice

In addition to the calculated indicators, there are still a large number of features that you need to pay attention to when choosing a propeller:

- The number of blades will have an impact on driving performance in the first place. It is recommended to choose a three-blade model, options with 2 or 5 blades are not actually used. Devices equipped with 4 blades are used when traction is needed. Their use is advisable in case of the need for increased carrying capacity, if the features of the gearbox do not allow to increase the screw diameter.

- The shape of the blades should also be chosen correctly, here it is primarily taken into account that models with an increased curvature accelerate cavitation. In addition, the leading edges should not be too sharp, it adversely affects the working parameters.

- Particular attention should be paid to the material of the propeller. The most reliable, durable and durable models are made of stainless steel of the new generation. However, for boats equipped with low power engines, especially when used in freshwater bodies, devices made of aluminum-silicon or aluminum-magnesium metal alloys are also suitable.

How to determine if the screw is suitable

To understand whether the existing propeller is suitable, you can remove the speed measurements at maximum and minimum loads, while the indicator must be within the limits defined by the manufacturer.

The following are specific examples of matching and non-matching selected devices:

- With minimal loads, the engine shows the number of revolutions declared by the manufacturer; At maximum loads, there is no serious movement resistance, it is possible to go on gliding. This demonstrates the versatility of the propeller, it was chosen correctly.

- Under no load, the engine does not produce the stated number of revolutions, problems arise when exiting to gliding. This situation clearly demonstrates that a screw with a too large pitch index was selected.

- Torsion occurs: the motor makes too many revolutions, exceeding the figures set by the manufacturer; while the speed of the boat is far from the maximum limit. This indicates that a screw with a higher pitch is required.

- Properly selected cargo screw will allow you to go out on the gliding without any problems, even with a full load of swimming means, a small loss of speed in this situation is normal.

- The maximum speed of the engine and the speed of the boat are achieved only with a slight loading of the swimming equipment and the hydraulic lift is in the upper position, similar situations are observed when installing high-speed screws.

Propeller protection

Operating rules

Even the most durable and reliable propellers are more vulnerable, this is the most fragile part of the boat. Below is a list of rules, compliance with which increases safety and has a positive effect on the operating life of the device:

- It is allowed to turn on the reverse only with full confidence that the propeller has enough depth. It is better not to risk once more and several times push off from the shoal with the help of oars.

- It is necessary to monitor the condition of the blades., since any deformation, irregularities and potholes interfere with the full functioning of the screw and are able to disable it.

- With the passage of the vessel near the most problematic areas of the reservoirwhich are shallow waters and a variety of underwater obstacles, you need to remember to use a hydraulic lift.

- It is constantly necessary to ensure that the propeller does not even briefly contact the bottom surface. - this is a basic condition for ensuring long service life.

Summarizing, we can bring the following tips regarding propellers and their use:

- It is not recommended to additionally coat such devices with paint, since in the absence of water-repellent properties, the surface will soon begin to peel off strongly, which will impair the functioning of the screw. As a result, the speed will fall even with an increase in the number of revolutions made.

- It is best to purchase propellers from major manufacturers who have established themselves on the good side and have a fair amount of positive feedback. Such companies give a long warranty on their equipment and often give pre-test selected models.

- To ensure the straightness of the vessel, you can install two screws with different directions of rotation. It must be remembered that the installation of several devices having the same rotation will contribute to the slope of the swimming means to one of the sides.

Instruction

Determine the basic parameters screwand for the outboard motor. They are the diameter itself screwand his step. From these parameters, given the power of the engine, depends on the maximum speed of the boat. Distance in inches screwom in one turn, there is a step screwand outboard motor.

Find in the designation put on the rower screwe, diameter and pitch screwbut. For example, the inscription 9.9x13 means that screwand for the outboard motor, the O is 9.9 inches at a pitch of 13 inches.

Look in the boat manual motor What maximum speed he can develop at full throttle, with the throttle valve open. Accelerate the boat to maximum speed. Using a tachometer, measure the rotational speed of the motor shaft, usually it does not exceed 5500 rpm.

Pay attention to the speed of rotation of the shaft with the maximum open damper. If it is less than the recommended maximum speed, then take the readings of the tachometer as the maximum speed of this type of rowing. screwbut.

Calculate the step screwand outboard motor. One inch step screwa is about 200 rpm Find the difference between the readings of the tachometer and the passport maximum revolutions, divide it by 200. Divide the resulting value by the gear ratio of the outboard motor. If you finally get the number 2, therefore, for this outboard motor, it is more expedient to use another rowing screwhaving a pitch of 2 inches less. With new screwyour ship will reach its planned maximum speed.

When choosing screwand to the boat motor stick to a certain rule. Use propellers with a large pitch for high-speed light boats, and with a smaller pitch - for slow-moving and heavy ones. Change step screwand the outboard motor is the only way to harmonize screw with the engine and with the boat.

Whatever the roomy modern hard drives, sooner or later they turn out to be full, and then there is a need to connect second screw - more correctly, the hard drive.

Instruction

Unplug the system unit from the power supply and remove the side panel from the case, unscrewing the fasteners screws. If your hard drive is connected to the motherboard via the IDE interface, you will use a wide 80-pin gray cable with two or three